Polymer Chemistry

Pioneering Innovations

ENTEX Rust & Mitschke GmbH is the leading manufacturer of Planetary Roller Extruders. ENTEX has over 160 intellectual property rights registrations to its name since its founding. The company’s product portfolio also includes calendar rollers and tempering systems.

Pressure-sensitive adhesives (PSA)

Solvent-free mastication and homogenisation with ENTEX equipment. Targeted and precisely controlled reactions guarantee the same homogeneity and viscosity throughout the extruded material.

Hotmelt (solvent-free)

Targeted meltability of different formulation components, extremely short compounding times of just a few minutes, effective cooling over a short distance, and a low-shear and material-friendly compounding process: the Planetary Roller Extruder can do it all.

Chemicals

Innovative mixing and reaction units from ENTEX encompass multiple process steps – significantly shortening the procedure. Temperature control, pressure measurement and degassing are all brought together in a single, coherent process structure.

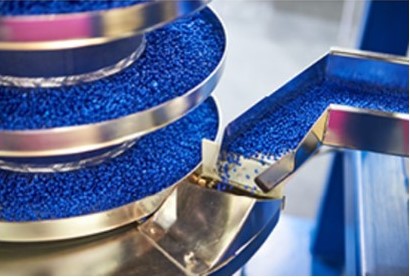

(Bio-) Plastics

Continuous processing, gently processing temperature-sensitive materials, excellent material quality, high-performance degassing, efficient self-cleaning, diverse processing possibilities. All of this is on offer from ENTEX extruders for (bio-) plastics.

Recycling

With outstanding homogenisation, precision temperature control, systematic process reactions, effective degassing, a material-friendly compounding process and effective cooling, we do more than think green. We act. ENTEX: Protecting future generations.

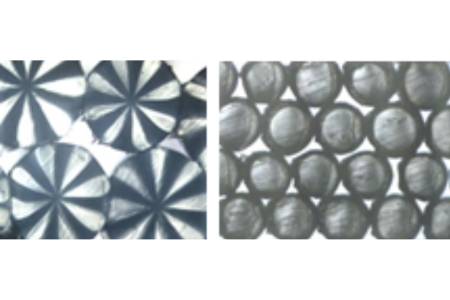

Conventional PVC extrusion

Be it flooring or garden furniture, pioneering technology from ENTEX is the best choice for compounding and granulating thermally sensitive materials.

Direct PVC extrusion

Producing dry blends was expensive. Now it is no longer necessary. Save time, energy and money with continuous direct extrusion from ENTEX. Also suitable for rigid PVC (uPVC).

Rubber And Elastomers

Process all formulation components in a single step thanks to optimised tempering. Move away from discontinuous processing – with continuous processing you can enjoy the same excellent material quality throughout the process while being able to take advantage of a large number of processing possibilities.

Silicone

Enjoy a technological advantage – by achieving desired viscosities more quickly, optimising dwell time control and employing high-performance degassing. Innovative, reactive extrusion process systems from ENTEX for your premium products.

FET is a leading supplier of state of the art process technology and equipment for the man-made yarns and fibre extrusion industry.

FET was established in 1998 with the firm objective of achieving technical excellence in our field and helping our customers to efficiently produce high value textile materials. This background has provided FET with a sound base for success and growth over this period. Our ongoing strategic objective is for controlled expansion year on year, extending our portfolio in response to customer demand.